Unboxing

back contact technology

It is for obvious reasons that leading module manufacturers focus eyes

and efforts on back contact cell- and module technology.

Reliability, maximum power harvest, more freedom of design and a

sturdy, sustainable product architecture are setting the newest standards.

It is only a matter of time until it will be mainly preferred worldwide.

But there is more to a premium quality product.Let's share a few of our considerations and selections, justifying the decision for back contact

and our supply chain from day one ...

Fluoropolymers in standard PV modules are largely made of polyvinylidene fluoride (PVDF) or polyvinylfluoride (PVF), also known as Kynar® and Tedlar®. These fluoropolymers complicate thermal degrade or cost-effectively recycle of polymeric backsheet material. Furthermore, thermal degradation (or: in case of fire) of fluoropolymers leads to toxic release of hydrogen fluorides with amounts beyond permissible regulations.

The presence of fluoropolymers, halogenated-flame-retardants, etc. also increases the potential formation of dioxins at End-of-Life treatment stage. Therefore, the option of typical landfilling poses an equal risk if the fluoropolymer backsheet material leaches into the atmosphere and contaminate the soil and waterbodies.

In conclusion: the use of fluoropolymers or halogenated polymers in PV modules should be avoided and alternate PET based or biobased backsheets should become the obvious standard.

This no-brainer, being more expensive, is still far from becoming an industry standard. However, fluor-free Energyra modules are way ahead!

It's an unconvenient truth: lead pipes are being replaced all over the world, while solar panels in which lead is an important component are still produced en exported on an enormous scale. This lead is needed for the ribbon coating and soldering paste for interconnecting the cells.

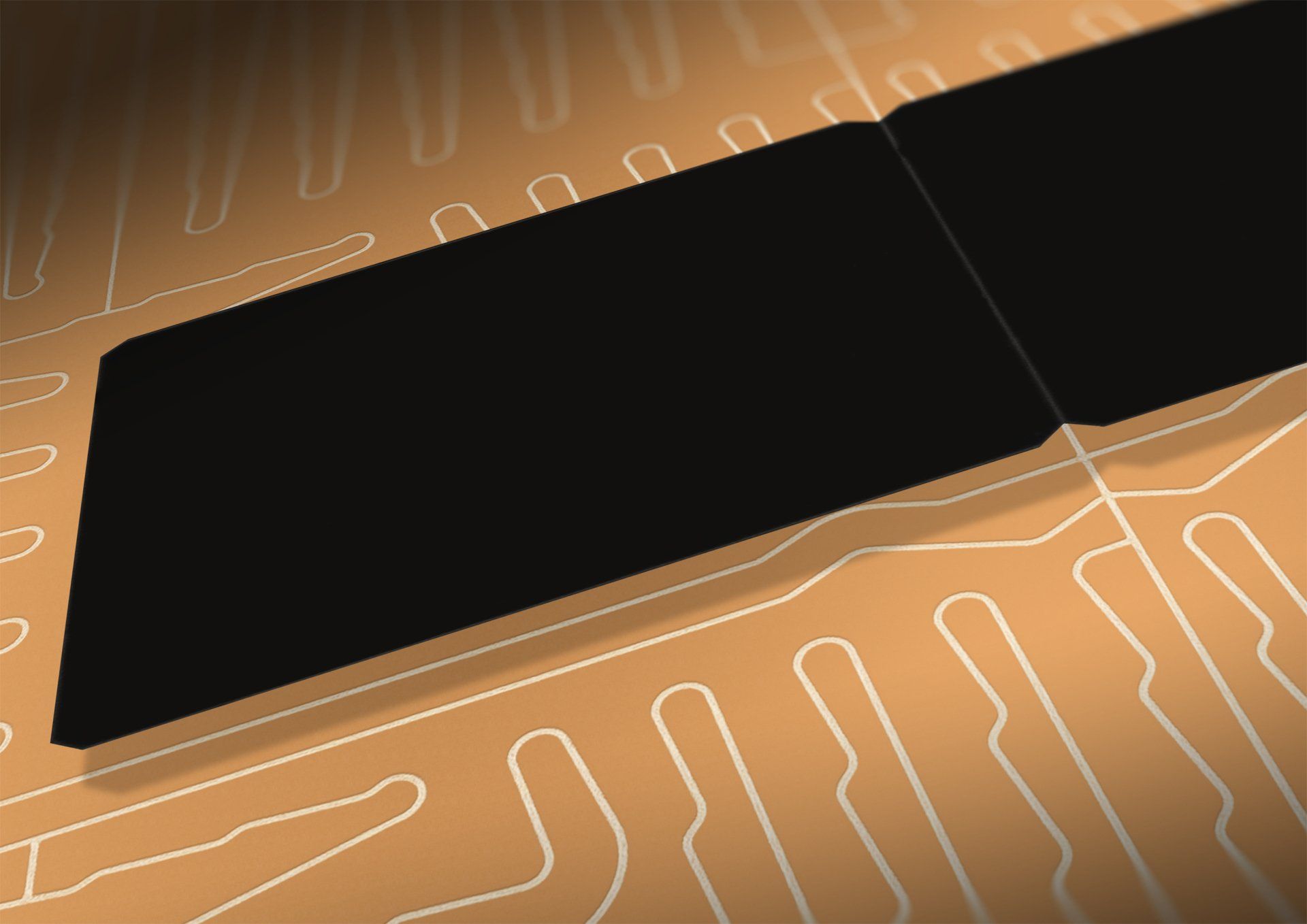

Energyra modules, based on back contact technology, have no ribbons at all and our contacting, derived from the automotive industry, is 100% leadfree. We have created this freedom in our product design by applying (printed circuit like) conductive backsheets.

This resulted in an additional great advantage: a full redundant interconnection design of the module, while limiting the thermal stresses, caused by the countless temperature driven cell expanding and contracting during the product life cycle. So, our module feature an extremely sturdy, metal-based, environmental barrier as well.

Energyra introduced the first PFAS-free module in 2018. Our PFAS-free approach now appeals to more and more parties who want an environmentally friendly solution. They know how to find us.

PFAS is an umbrella term for a group of chemical substances that are man-made. The substances are water, fat and dirt repellent. They are widely used in solar panels, but also in all kinds of everyday products, such as fire-fighting foams, packaging materials, clothing and cosmetics. PFAS substances enter the environment through emissions and through the use of PFAS-containing products.

An EU decision on PFAS was made in 2019: one kilogram of dry soil may only contain a maximum of 0.1 micrograms of PFAS. Moreover, it may no longer be moved, resulting in the PFAS crisis, with many projects and works on-hold. A big problem for construction companies, dredging and earth moving companies and farmers.

With PFAS-free solar panels, Energyra offers a step forward.

Energyra modules feature a patented Royal DSM nano-coating invention: KhepriCoat. This offers record-breaking performance in light transmission, outperforming all other coatings on the market.

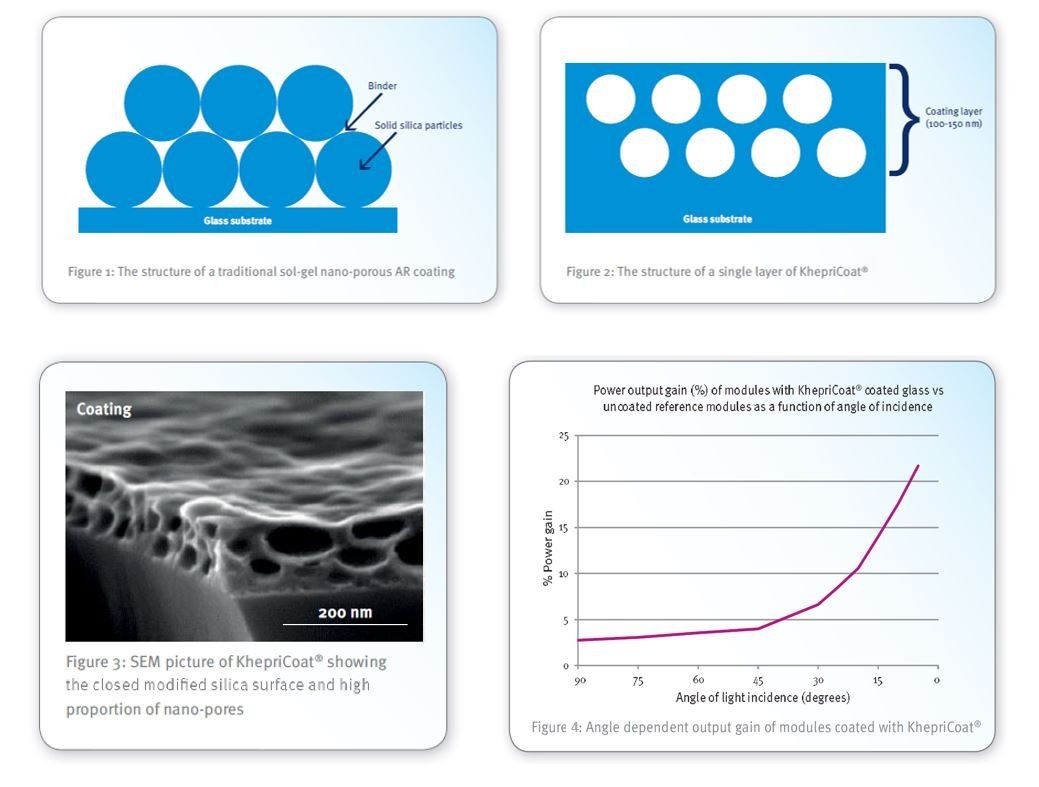

Where air meets glass, about 4% of the light at a perpendicular angle is reflected. This percentage is way higher when the light angle of incidence increases. Traditional single-layer AR-coatings consist of solid silica nano-particles 'glued' together with a binder so that spaces between the particles act as nano-pores (image 1).

The structure's open surface makes the silica layer of the coating vulnerable to hydrolysis, when exposed to extreme weather conditions.This can cause a fast detoriation of optical and mechanical properties. Khepri-coat (nowadays part of the Covestro portfolio) avoids this trade-off by turning the structure of the coating inside out. Instead of being formed in the spaces between solid nano-particles, the nano-pores in KhepriCoat are actually hollow particles (image 2).

Furthermore, because the coating layer and its glass substrate have similar compositions (image 3), the adhesion of the coating layer to the glass surface is excellent.

And because it has a smooth, 'closed' surface, the risk of hydrolysis is sharply reduced enabling the coating to withstand extreme weather conditions.

In addition, this prevents dirt from penetrating the coating's surface, making it very easy to clean. If some rain doesn't already.

At Energyra we only use the original Stäubli MC4 connectors to ensure that your installation is as safe as possible.

MC4 Connectors are a small but important component of the solar installation. There are many benefits of genuine MC4 connectors, however with so many cheap copies available today, remember original MC4 connectors are used to reduce the risk of overheating which could lead to a fire.

For those who didn't know yet, MC4 stands for the Swiss manufacturer Stäubli Multi-Contact and size (4mm2) of the contact assembly pin. MC4 Connectors have been used to equip almost all solar panels for the last decade.

While it may seem difficult to distinguish a genuine MC4 connector from a copy, the technical comparisons -and risks- differ greatly. Using different brands can result in poor connections, possibly resulting in:

- System failure, and more re-work

- Temperature-rise, system overheating, or even fire.

- Electrocution, when touching a connector where rain and dust have entered

So, no doubt: at Energyra you can be sure you will get the benefits and the safety of original MC4 connects.

Nearly half the world’s supply of silicon cells, a key component used in the solar power industry, is likely to depend on forced labour. Obviously, this won't be called forced labour, let alone slavery. More likely are mystic names, like surplus labour and labour transfer programmes. By selecting almost unrealisatic low-priced non-Western mass produced PV, customers unknowingly support these practices.

At Energyra, we care. We source our materials smartly. Whenever possible, we prefer around the corner, made in Europe. Which by the way also results in a significant lower carbon footprint.

Where the more complex supply chains came in, we've carried out (or participated in external) research to increase our understanding and knowledge to the maximum extent. Creating insight is a mandatory standard of our sourcing process. We will never shy away from sensitivities: no forced labour simply is a spec.

This brings us peace as well.

Quality cells combined with high-quality European solar glass and a sturdy frame make Energyra modules virtually immune to micro-cracks in real-world conditions.

Micro cracks are small cracks in solar cells. They are impossible to see with the bare eye, but truly impact the performance of a PV system. A feared enemy of traditional (busbarred or wired) modules.

Most solar cells are comprised of very thin silicon wafers, usually around 0.15-0.20 mm thick. These have some ability to flex, but simple pressure or stress can induce micro-cracks. Newbies in solar industry often unknowingly create micro-cracks by throwing boxes of gear on top of stacked panels. Standing or kneeling on panels during installation is also a contributor to micro-cracks.

Energyra back contact modules are more robust than conventional modules because of the integrated Conductive Backsheet (CBS). This innovative copper design ensures optimal contact with an incredible number of contact points across the entire cell. It is an additional (metal) environmental barrier to protect the cells and keep them sturdily in place, and actually strengthens the contacting architecture.

If a micro-crack should occur, the cell will still be in perfect contact with the copper that conducts the energy, effectively designing the negative effects of microcracks out of the module.

Our premium quality PV Modules

EclectIQ

Full-black

Monocrystalline

Small roof, high yield

When every square meter of roof surface counts (and when doesn’t it) modular efficiency (KWh/m2) is essential. Energyra® ECLECTIQ solar panels offer an unprecedented module efficiency, in addition to great green back contact technology efficiency.

DynamIQ

LIGHTWEIGHT

project PV module

Ultra light

From 1.8 kg/m2 and up, depending on the need or application. While maintaining the proven, highest power harvest per m2 (sqft).

Availability of our Modules

Our modules are distributed and supported by Rexel to your own installer in the Benelux. Contact your installer for a suitable quotation and simply ask for Energyra PV-modules: they will know exactly what to do.

Do you have specific questions or require industrial or mobile applications outside of the Benelux? Contacting Energyra is always a good idea!