The easy choice is yours

Back-contact PV:

Great performance

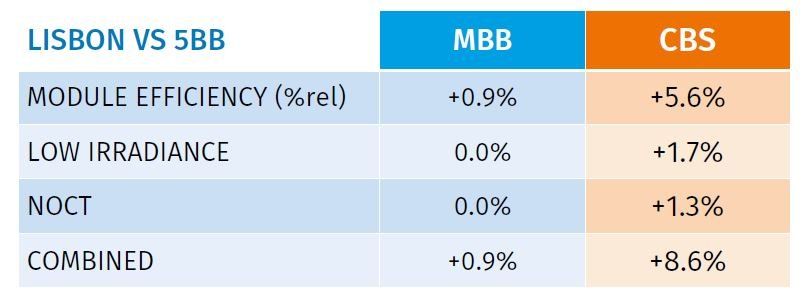

We are glad to highlight some of the key benefits of the backcontact platform vs. traditional tabbing-and-stringing and/or wiring technology. Research, indepently carried out by Royal DSM and Silfab, covers the differences between multi-busbar

(MBB, 5 >) and the Endurans Conductive backsheet technology applied by Energyra.

Market-relevant module designs are compared for each technology starting from the same PERC solar cell and with a focus on:

- Module efficiency

- Low irradiance behavior

- Nominal operating cell temperature (NOCT)

Summary: unrivaled yield

Combined performance gain +8,6%

Starting from the same PERC cell, a benefit of up to 8.6% in kWh/m2 can yearly be expected from all Energyra modules.

This higher module efficiency is enabled by the back contact interconnection system:

- The ability to use full cells (rather than half-cells) while still achieving a high module power

- An optimized low-irradiance performance

- A lower NOCT, due to the increased heat spreading in the conductive backsheet.

Therefore, using a CBS in solar modules enables an improved energy yield,

improved module aesthetics, and improved long-term durability due to reduced thermo-mechanical stresses.

Backcontact combined performance gain:

- + 8.6% (STC Lisbon, kWh/m2)

- + 9.4% (STC Amsterdam, kWh/m2)

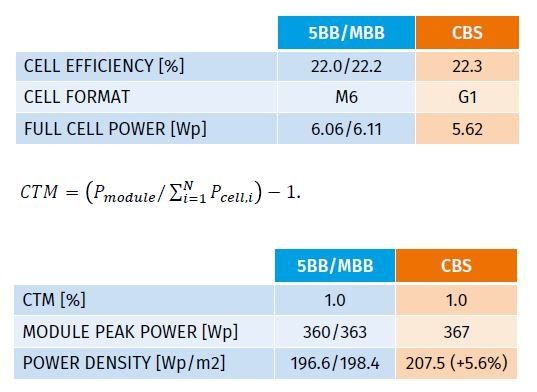

Higher Module Efficiency

Increase of Power Density: +5.6%

The comparison considers PERC cells that went through the same manufacturing process, with 2 distinctions:

- Cells for the MBB and CBS module have an efficiency gain of over the 5BB module, due to the reduced front metallization and reduced resistive losses

- 5BB/MBB modules are built with M6 format cells (166.0x166.0mm) and CBS modules with a G1 cell (158.75x158.75mm), due to the availability of MWT cells at the time of this research.

Additional gain of up to 8% for CBS is nowadays very relevant, due to the improved availability of larger cell formats such, as M4 and M6 in the daily operation of Energyra

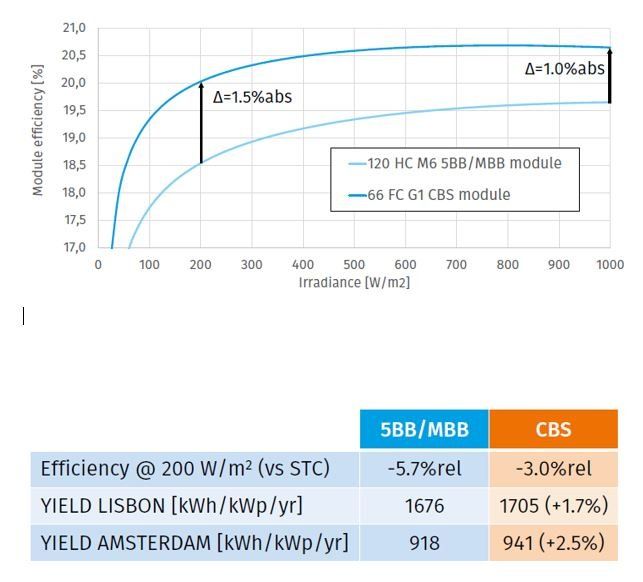

Better Low-Light Behavior

Increased Yield (STC, Amsterdam): +2.5%

The use of half-cells is becoming more common in the PV module industry. After all, reducing resistive losses in increases nameplate power at STC.

Due to the reduced cell current, half-cell modules generally have a lower series resistance than full-cell modules. This improves module peak power, but clearly reduces low-irradiance performance.

CBS modules enable a high module power by using full cells. Furthermore, CBS optimizes low-light performance by tailoring series resistance in the design.

The effect of the low-irradiance behavior on energy yield has been estimated using PVSyst. The table below shows two simulated annual yields (in kWh/kWp):

- Lisbon: GHI =1758 kWh/m2/year, ~ 35% diffuse

- Amsterdam: GHI = 965 kWh/m2/year, ~ 58% diffuse

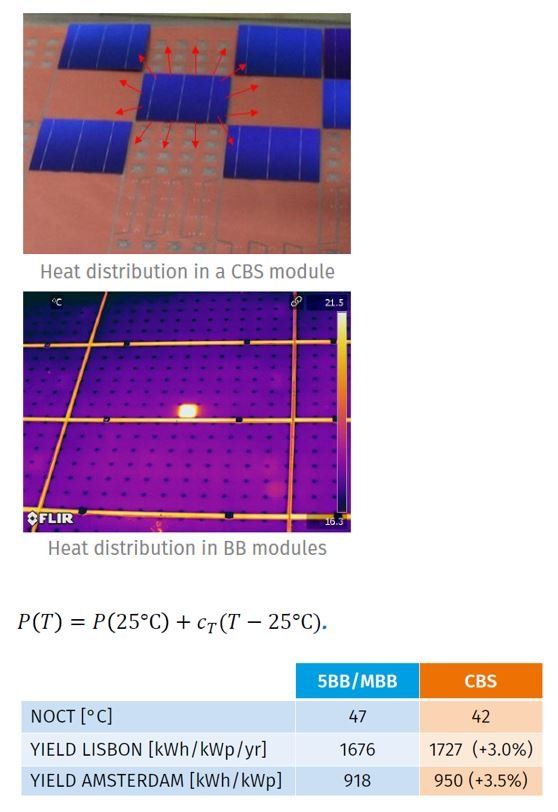

Lower NOCT

Better heat distribution: yield + 3.5%

A module’s power and energy yield is a result of its operating temperature and temperature coefficient, driven by cell technology. The NOCT (Nominal Operating Cell Temperature) for CBS modules was found to be 5-7ºC (41-44.6°F) lower than for conventional modules, resulting in 3.5% yield increase.

The NOCT is a fine predictor for the operating cell temperature. This is measured at 800W/m2 irradiance, an air temperature of 20°C (68°F), and a wind speed of 1m/s with open backside mounting.

The module power can be expressed as a function of temperature:

𝑃(T)=𝑃(25°C) +𝑐𝑇(𝑇−25°C). In traditional modules, heat is primarily dissipated from the rear of the cells. In a CBS module, the presence of the conductive sheet increases heat spreading.

In section 2, this effect had not yet been included in the simulations (an NOCT of 47°C was assumed for all module). Including the reduced NOCT, see the graph.

The most promising technology

In our factory near Amsterdam we assemble solar panels with an extremely high degree of automation (Industry 4.0) and AOC/AI (Auto Optical Inspection/ Artificial Intelligence) control. As a result, our back contact modules are assembled more accurately and continuously monitored for quality.

- Fully-robotized

- AOC/AI vision technology

- HD camera inspection

- Traceability

- Extensive in-house QA lab

Green, greener, greenest

The ingredients of a traditional solar panels are not always as green as their generated electricity.

At Energyra, we take care of every single aspect of creating a green, durable product. Our supply chain is slavery-free.

The majority of the materials are purchased from Europe. Unlike traditional modules, Energyra® solar panels do not require

solder connections (containing lead) for the cells. In addition, our backsheet is fluorine- and PFAS free. The connection cables are halogen-free.

Our encapsulation film lacks the usual vinyl compounds. To us, it is furthermore only common that our own production facility runs on green energy.

Smart partners

ISC Konstanz is involved in steadily increasing the efficiency of photovoltaics and simultaneously reducing their cost. With Energyra, ISC shares quite some goals: to make solar clean, and green energy affordable and accessible around the globe: the only way the energy transition can succeed.

TNO Solar (v/h ECN Petten) focuses on increasing the power harvest of solar panels, reducing costs and improving options for integrating aesthetically pleasing PV in the human environment. TNO cooperates with Energyra on innovative technologies for solar modules based on back contact technology.